- What is wood?

Softwood: conifers

75% of all lumber production

Used for framing lumber, sheathing, siding, flooring

Hardwood: deciduous trees

Used for finished wood products: interior trim, flooring, doors, and furniture

- Wood growth

Bark

Cambium layer - outer layer of active cell growth (summer wood)

Sapwood - carries nutrients to leaves - light color

Heartwood - no longer active

Meduliary rays - carries nutrients horizontally across grain

- Physical properties of wood

Moisture content

- Natural defects in wood

Knots - branches become enclosed within the wood as the tree grows

Shakes - grain separation between growth rings

Pitch Pockets - grain separation which contains solid or liquid resins

- Damage which may occur to wood

Rot ("dry" rot)

can occur when moisture content exceeds 30%

Caused by bacteria which lives in the moist wood and ingests the wood fibers

Insects

Termites

Carpenter ants

Carpenter bees

Prevention and treatment

Injection of chemical into wood to prevent rot and insect infestation

Termite shields around foundation

Termite treatment for extermination

- Wood manufacture

- Old growth vs. New growth forests

- Sawmills

- Milling and surfacing

- Cross-sectional sizes of framing lumber

2X2: 1 ½" x 1 ½"

2X4: 1 ½" x 3 ½"

2x6: 1 ½" x 5 ½"

2x8: 1 ½" x 7 ¼"

2X10: 1 ½" x 9 ¼"

2X12: 1 ½" x 11 ¼"

- Typical lengths of framing lumber readily available

from lumber yard:

8 feet

10 feet

12 feet

14 feet

16 feet

18 feet

20 feet

- Sizes of finish wood: 1" nominal thickness is actually 3/4" thick

- Veneer production

- Oriented strand board (OSB)

- Grading of wood members

- Grading standards set by industry organizations such as the Southern

- Grading of wood is done visually

- Stress grading

- Fabrication of structural wood members

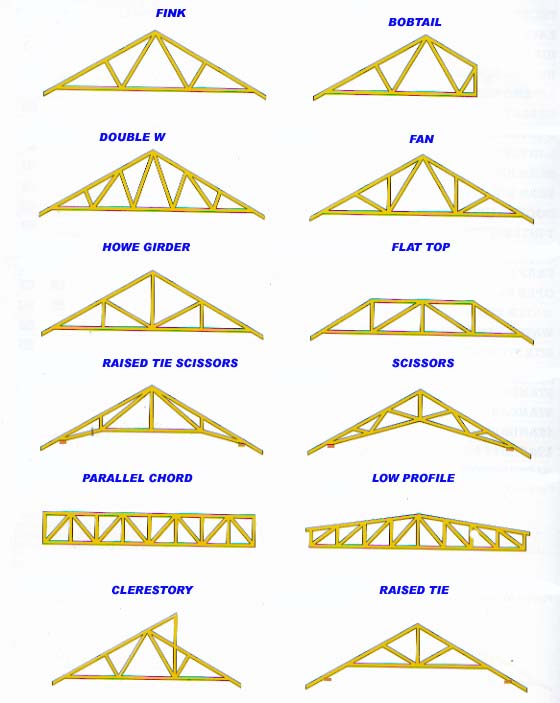

Roof trusses

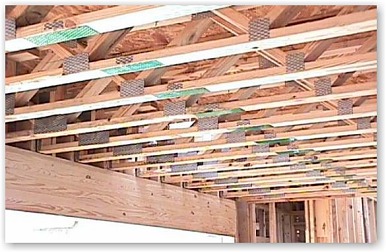

"TJI" Truss-Joist "I" sections (Note: these are not be permitted in Elmhurst)

Web truss joists

TJL

Paralam beams

Microlam LVL beams

Timberstrand LSL

- Selection of wood member sizes

- Construction in field

- Fasteners

Nails

History

Forged

Wire cut

Contemporary nail types:

Common nails

Common Coated (CC) nails

Finish nails

Cut nails

Galvanized nails

Roofing nails

Stainless Steel nails

Copper nails

"Pennyweight" (originally meant the cost of nails per 100 nails in England)

10d (reads as "10 penny") common nails are 2 1/2" long

16d common nails are 3 1/2" long

"Cordless" nailer

Pneumatic nail gun

Wood screws

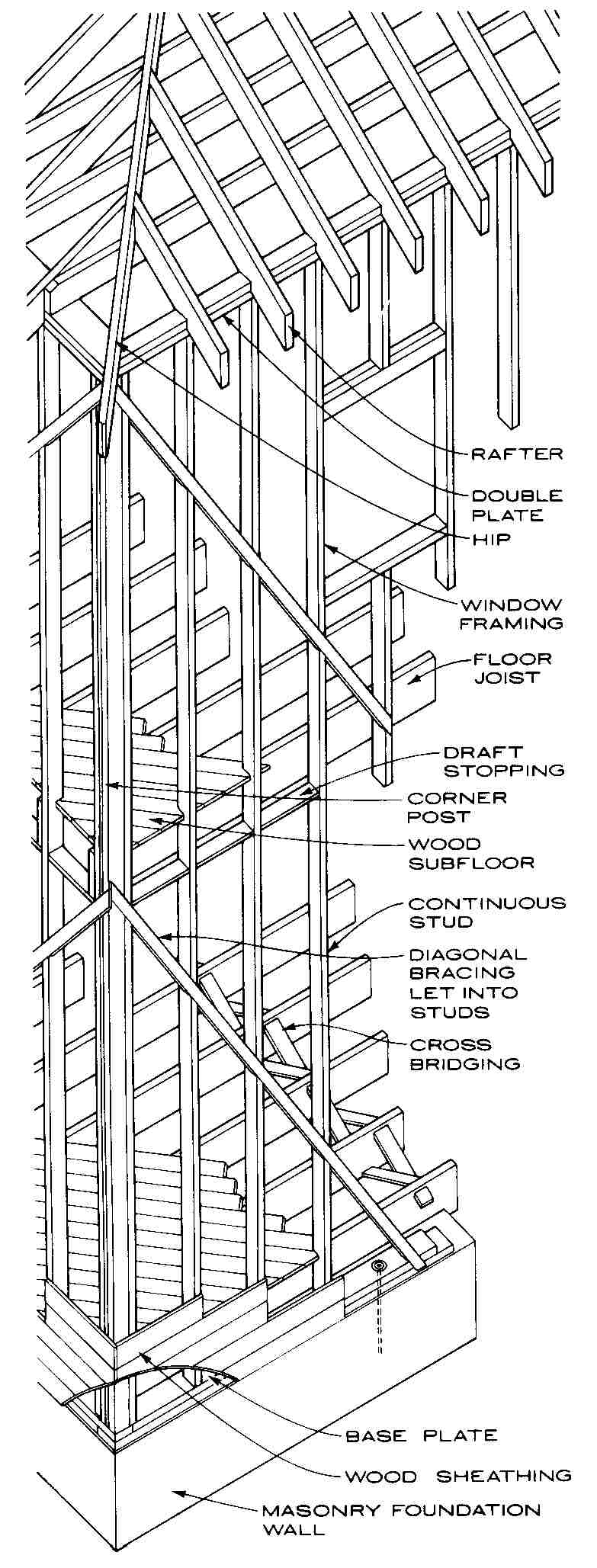

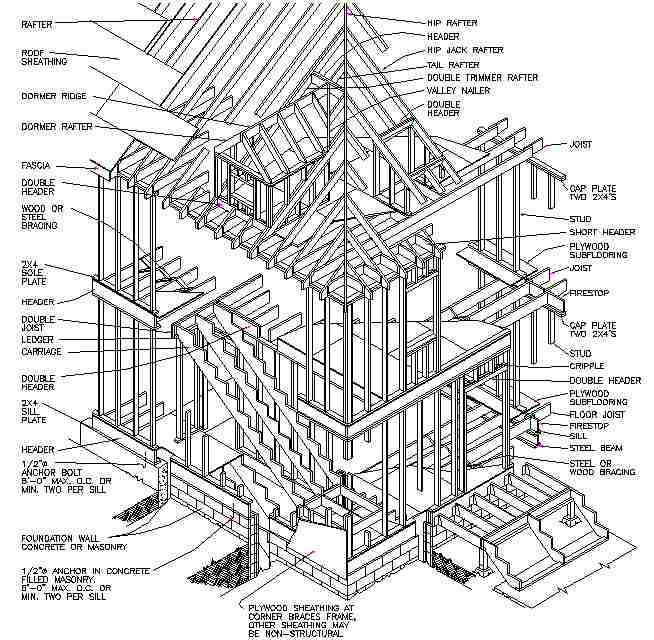

- House framing

History

"Heavy Timber" with nogging

Balloon framing invented in Chicago

Western Platform framing

Structural design

Purpose of structural design

To prevent or minimize movement in the building caused by loads which are impinged on it

Structural action

Compression

Tension

Bending

Shear

Torsion

Compound

Deflection

Shortening

Crippling

Tearing

Creep

Relaxation

Fatigue

Types of loads

Gravity loads

Dead loads

Live loads

Lateral loads

Wind

Earthquake

Torsional loads (twisting)

Method of structural design

Calculations based on structural formulae

Span tables in codes

Structural elements in buildings

- Foundations

- Walls

- Columns

- Girders

- Beams

- Joists

- Floor or Roof Deck

- Trusses

- Rigid frames

- Arches

- Vaults

- Domes

- Rafters

- Purlins

- Space frames

- Lateral bracing

- Moment connections

- Suspension members

Typical structural members in houses

Studs (walls):

Typical: 2X6 @ 24" o.c.

Even better for insulation: 2x6 @ 16" o.c. with horizontal 2x3 strapping @ 24" o.c. on interior

Best for insulation: 2 layers of 2x4 @ 24" o.c. separated by 12" with cavity filled with insulation

Bracing to stiffen exterior walls against "racking" (sway)

Plywood sheathing

OSB sheathing

Gypsum sheathing with plywood at corners

Thermas sheathing with plywood at corners

Let-in bracing (1x4 diagonally nailed to routed out wall studs)

Metal bracing (Tee shaped metal strip saw-cut (kerfed) into face of wall studs

Beams

Lintels above openings

Exterior openings: use 2 - 2x10s with 2X6 horizontally spiked to vertical members, top and bottom, which makes a 51/2" width - insulation in 2 1/2" wide space between vertical 2x10s.

Interior openings: use 2 - 2x12s with 1/2" thick plywood filler between, which makes a 3 1/2" width

Joists:

Depth and spacing depends on span and species of wood used

Typical 2x10 @ 16" o.c.

Rafters:

Depth and spacing depends on span and species of wood used

Typical 2x8 @ 16" o.c.

Deck (floor and roof)

Typically 3/4" thick tongue-and-groove plywood

Roof trusses:

Member size usually 2x4s joined with gang-nail plates

Trusses are designed by manufacturer based on code-required loads

- Heavy Timber

Member minimum nominal sizes by code

Floors - 2" thickness

Beams - minimum 4" x 4"

Columns - minimum 4" x 4"

All members must be exposed to interior spaces and must be visible

Solid sawn wood

Glue laminated wood (GluLam)

Trussed beams

Wood heavy timber trusses

Gusset plates

Split ring connectors

Bolts

Types of trusses

Bowstring King post Queen post Warren truss

Pratt Truss

Howe Truss

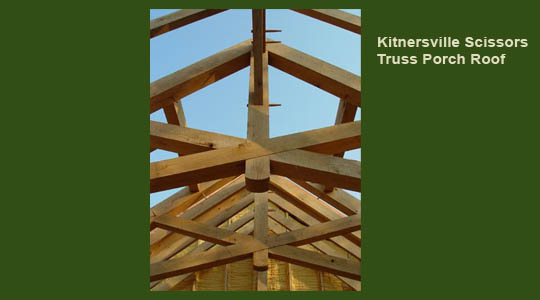

Scissors truss

GluLam Rigid frames

GluLam Arches

- Plywood

Definition of plywood:

Flat panels of wood made up of wood veneer sheets 1/10" to 1/16" thick, placed at right angles to one another and glued together

Types of plywood

Construction (softwood)

Decorative (paneling, hardwoods)

Grades

Engineered Grades

C-D Interior Structural I

C-D Interior Structural II

CC Exterior

Stamped with 2 numbers on each piece:

1st number: Maximum support spacing for use as roof sheathing

2nd number: Maximum support spacing for use as subflooring

Interior appearance grades

N: select all-heartwood or all-sapwood for natural finish

A: smooth, for paint finish

B: solid surface veneer

C: tight knots, some splits

D: knotholes not filled

Overlays

Resin impregnates fiber sheets

High density (for use as concrete formwork)

Medium density (for use in doors)

Decorative Plywood

Softwood core and hardwood veneers from over 50 species (Luan, walnut, oak, birch, and gum are most popular)

Cut

Rotary

Flat (plain) sliced

Quarter sliced

Half round sliced

Rift cut

Related panels:

Particleboard

Hardboard (Masonite)

Oriented Strand Board (OSB)

Fiber board (Homosote)

Applications of plywood

Flooring structural decks

Underlayment

Sheathing

Walls

Roofs

Siding

Stamped or sawn patterns

Pressed figures

Siding

Clapboard

Board and Batten

Tongue and groove boards

T-111 plywood

- Wood for interior finishes

Species

Oak

Maple

Cherry

Walnut

Butternut

Teak

Honduras mahogany

Birch

Poplar

Ash

Cut

Plain sawn

Quarter sawn

Rift sawn

Applications

Doors

Windows

Door and window casings

Wainscot

Baseboards

Base shoes

Chair rails

Plate rails

Picture rails

Crown moldings

Stairs

Paneling

Millwork

Ceilings

Floors

Free water and embedded water

Green lumber contains up to 200% moisture

Ideal moisture content:

Framing lumber: 15% - 19%

Interior finish wood: 6% - 12%

Shrinkage: for every 1% loss of moisture content below 80% wood will shrink 1/30 of total volume

Methods of reduction of moisture content

Air drying

Kiln drying

Density of wood (at 15% moisture content)

Pine: 40 pounds per cubic foot

Fir: 35 pounds per cubic foot

Structural properties of wood

Strength of wood will vary with the wood "species" (type of tree) and the quality of the piece of wood, e.g. how many knots it has in it

Industry organizations publish standard strength values for various species and quality

Allowable working stresses

Extreme fiber in bending (Fb) = 1200 to 1500 psi

Tension parallel with grain (FT) = 900 to 1200 psi

Horizontal sheer (FV) = 75 to 100 psi

Compression perpendicular to grain (F'C ||) = 385 to 565 psi

Compression parallel to grain) (F'C =) = 500 to 1800 psi

Modulus of Elasticity (E) = 1,200,000 to 1,800,000

Pine Inspection Bureau (SPIB) or the Western Woods Products Association (WWPA)