Formed or cut modular units of solid material put together by hand and joined with a mortar to make a larger strong unit

Term derives from Anglo-saxon root of "mace" which means a hacking tool

Clay masonry: Brick

Historical categories

Mud brick

Burned brick

Terra Cotta

Modern categories

Paving brick (100% solid)

Brick (75% solid)

Hollow tile (less than 75% solid)

Terra Cotta (burned to a higher temperature and contains some old clay masonry materials)

Raw materials

Surface clays

Shales (clays subjected to natural pressure and hardened almost to slate)

Fire clays (mined at deeper levels)

Manufacturing process

Mining clay ("winning")

Storage of clay

Crushing clay & removing stones

Forming units - mixing clay with water in a "pug mill"

Stiff mud

Soft mud

Dry-press process

Burning

Drying 1 to 2 days at low heat

burning in "tunnel" or "periodic" kiln 2 to 5 days at 300? to 2400?F

Cooling 2 to 3 days

"Drawing" (removing brick from kiln

Blending and palletizing

Storage of finished product

Shipping

Material properties

Compressive strength: 1500 psi to 20000 psi, depending on type of clay and method of manufacture

Absorption (of water) - also know as "suction:" maximum of 20 grams of water per unit

Shrinkage: 4.5% to 15%

Sizes

Standard brick: 3 5/8" thick x 2 1/4" high x 8" long

Modular brick: 3 5/8" thick x 2 1/4" high x 7 5/8" long

Utility brick: 3 5/8" thick x 3 5/8" high x 7 5/8" long

Roman: 3 5/8" thick x 1 5/8" high x 11 5/8" long

Norman: 3 5/8" thick x 2 1/4" high x 11 5/8" long

There are other sizes but they are not as commonly available

Parts of a brick (terminology)

Face

Bed

Head

Frog

Core

Hollow Brick (25% to 40% solid) - looks just like brick from outside, but larger units - also known as "thru-wall brick"

Structural clay tile (less than 40% solid)

Grades

SW (Severe weather)

MW (Medium weather)

NW (No weather)

Admixtures

Concrete masonry

Types

Concrete masonry units (CMU)

smooth face block

split face block

ground face block

glazed block

pattern block

sunscreen block

pilaster block

jamb block

lintel block

bullnose block

solid block

Concrete brick

Materials

Portland cement

Aggregate

sand

gravel

blast furnace slag

expanded shale

expanded clay

coal cinders - hence the archaic name "cinder block"

pumice

water

admixtures - air entraining

Manufacturing process

Receive raw materials

Store materials

Mix materials

Mold units in steel forms

Cure units

Steam

Autoclave

Cube units (band with steel bands)

Store

Ship

Characteristics of concrete masonry

Compressive strength: 1000 to 1800 psi

Absorption: 5 pcf to 20 pcf

Parts of a block

Face shell

Web

Core

Edge flange

Sizes:

width: 7 5/8"

length: 11 5/8"

thickness:

nominal 2" "soap": 1 5/8"

nominal 4": 3 5/8"

nominal 6": 5 5/8"

nominal 8": 7 5/8"

nominal 10": 9 5/8"

nominal 12": 11 5/8"

Grades

Type I - limited moisture content

Type II - no limit to moisture content

Type N: General use

Type S: use only above grade and in walls not exposed to weather (interior)

Weights

Normal weight - 150 pcf

Light weight (use light weight aggregates) - 90 pcf

Stone masonry

Types

Sedementary rocks:

Limestone

Bluestone

Lannon Stone

Crab Orchard Stone

Sandstone

Metamorphic rocks:

Marble

Travertine

Slate

Igneous rocks

Granite

Traprock

Patterns

Rubble

Random ashlar

Coursed ashlar

Cutting

At plant

In field

Dressing

Mortar

Purposes

Bond units together

Compensate for small size variations

Embed metal reinforcing and wall ties

Visual interest - provides shadow lines and color

Components

Portland cement

Lime - made by adding water to quicklime, converting the calcium oxide to calcium hydroxide

sand - not larger than 1/4" in diameter

water

coloring

admixtures

Characteristics

Workability

Bond strength

Compressive strength

Watertightness

Plasticity

Color

Defects

Efflorescence - appearance of white powdery substance on face of brick caused by soluable salts in mortar and moisture in wall

Mix types

Type M: 1 part Portland Cement, 1/4 part lime, 3 parts sand: compressive strength: 2500 psi

Type S: 1 part Portland Cement, 1/2 part lime, 4 1/2 parts sand compressive strength: 1800 psi

Type N: 1 part Portland Cement, 1 part lime, 6 parts sand compressive strength: 750 psi

Type O: 1 part Portland Cement, 2 parts lime, 9 parts sand compressive strength: 350 psi

Type K: 1 part Portland Cement, 4 parts lime, 15 parts sand compressive strength: 75 psi

Masonry Cement - contains portland cement, sand and fillers - no lime, comes pre-packaged as types M, S, and N

Disadvantages: lower compressive strength & less water tightness

Advantages - no lime (therefore cheaper) and pre-mixed

Masonry Grout

Purpose:

fill vertical cores in masonry for vertical reinforcing

fill lintel blocks

fill voids in walls to make solid

Components

Portland Cement

Lime (optional)

Sand or gravel

Water

Characteristics

Pourability

coarseness

fine grout

coarse grout

Masonry Reinforcing

Horizontal

Spacing: every 2nd or 3rd courses

configuration

ladder

truss

material: galvanized steel

Vertical

Not always specified - depends on type of wall, height, and strength required

Material: #4 to #8 deformed bars

Flashing

Locations

Thru-wall flashing

Below sills

Above lintels

Joint between wall and roofing

Materials

Stainless steel

aluminum

PVC

Neoprene

Galvanized sheet metal

Copper

Types of masonry walls

Solid masonry

Plain (unreinforced)

Reinforced

Cavity walls

Veneer

Wood stud backup

Metal stud backup

Prefabricated

- Masonry workmanship

Most important part of masonry construction is quality of mortar joint

Moisture

Brick must be wet before laying to prevent excessive suction of water from mortar

CMU must not be allowed to become wet

Retempering of mortar - is allowed up to 2 hours from time of mix

Tools

Plumb bob

level

string

trowel

mortar board ("hawk")

Hod

Jointer

Position of brick in a wall

(specifications should list width first,then height, then length)

Stretcher

Header

Rowlock

Soldier

Sailor

Shiner (or Bull Stretcher, or Waler)

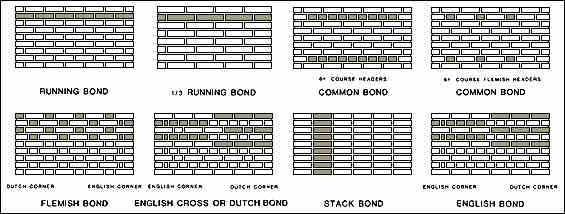

Bonds

Common bond

English Cross bond

Dutch bond

Flemish bond

Stacked bond

1/3 running bond

Thickness

Wythes - width based on brick or block stacks

Building codes

Engineering

Mortar joint types

Troweled

Flush

Struck

Weathered

Tooled

Concave

Vee

Raked

Parging

Cleaning and finishing

Brick - 2% solution of muriatic acid

CMU -

brushing

painting

staining

Masonry wall design

thickness vs. Height

Location of pilasters

engineering design

Masonry wall ties

Cavity walls:

one for every 4 ½ square feet of wall area

36" horizontal spacing and 18" vertical spacing

Veneer walls

one for every 2 sq ft of wall area

Maximum of 24" spacing in all directions

Lintels

Masonry lintel block reinforced and filled with grout

Steel angle

Masonry arches

Minimum of 4" bearing each side

Window sills

Stone

Brick

Metal

Concrete

Cavity space

Insulated

width - 2" min to 3" max

Expansion joints

spacing - 30 ft max

Fire ratings